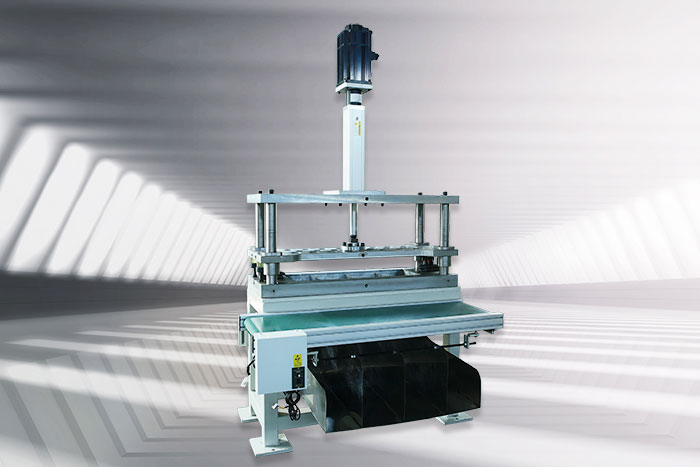

Dental Pressure Forming Machine

Dental Pressure Forming Machine

Product features

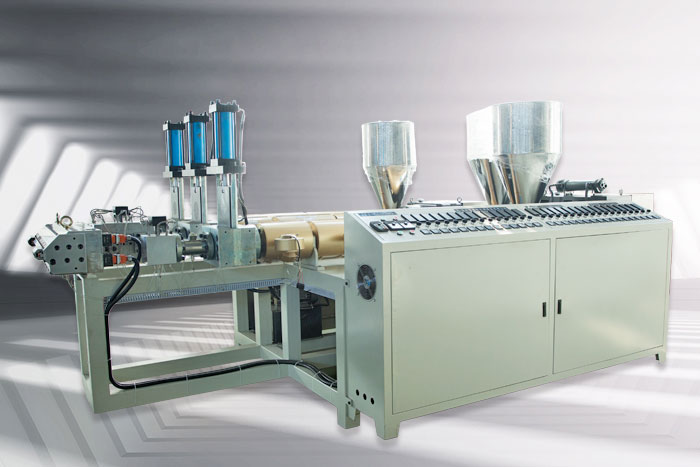

Our factory production plastic food box machinery and equipment, one step in place, complete the extrusion sheet and plastic molding all the processing procedures, with plastic particles and scraps processing directly molding products, can be widely used in food, electronics, toys, hardware and other packaging products production, its main technical characteristics and economic benefits are as follows:

1. The unit’s plastic suction device overcomes the disadvantages of low efficiency of the original batch forming. It replaces the process of using plastic particles to process sheet material, then heating sheet material, and then using a blister molding machine to process the desired product.

2. The unit with plastic extrusion machine and plastic molding machine, automatic feeding machine, punching and shearing unit together, synchronous work, to complete the required products.

3. The machine can be used for scrap material, waste and plastic particles mixed together to process and shape packaging products, PP, PE, HIPS and other plastic blister molding.

4. The machine can produce two or more layers, two color or more than two color products. Provide quality service for production.

5. The machine production speed is fast, the average area in 120mmX160mm calculation, each minute can produce 86 products, according to the thickness of the product requirements, can be adjusted at will to control the thickness of the product.

6. The machine reduces investment by about 20%, saves electricity by 35%, improves efficiency by 25%, reduces labor intensity and enhances economic benefits.

| Category/Model | φ65 screw | φ80 screw | φ90 screw |

| Motor power | 0.75KW | 0.75KW | 1.1KW |

| Operating speed | 25-32 S/min | 25-32 S/min | 25-32 S/min |

| Maximum forming area | 300x260mm² | 520x260mm² | 720x260mm² |

| Maximum forming depth | 60m | 60m | 70m |

| External dimension | 1900x650x1600mm | 1900x800x1600mm | 1900x900x1600mm |

| Weight | 600kg | 650kg | 740kg |

Our corporation since its inception, constantly regards solution excellent as organization life, constantly increase creation technology, increase merchandise good quality and continually strengthen business total quality management, in strict accordance while using the national standard ISO 9001:2000 for Factory Outlets China Non Woven Plastic Paper Packing Shopping Carton Box Cup Bag Plate/Straw Lid Foming Making Machine, We sincerely hope to establish some satisfactory relationships with you in the near future. We will keep you informed of our progress and look forward to building steady business relations with you.

Factory Outlets China Paper Cup Machine, Non Woven Bag Making Machine, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.