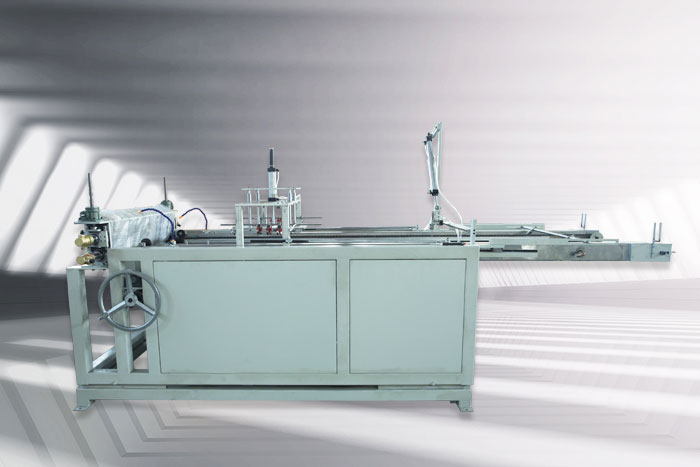

Thermoforming Machine

Thermoforming Machine

Product features

Our factory production plastic food box machinery and equipment, one step in place, complete the extrusion sheet and plastic molding all the processing procedures, with plastic particles and scraps processing directly molding products, can be widely used in food, electronics, toys, hardware and other packaging products production, its main technical characteristics and economic benefits are as follows:

1. The unit’s plastic suction device overcomes the disadvantages of low efficiency of the original batch forming. It replaces the process of using plastic particles to process sheet material, then heating sheet material, and then using a blister molding machine to process the desired product.

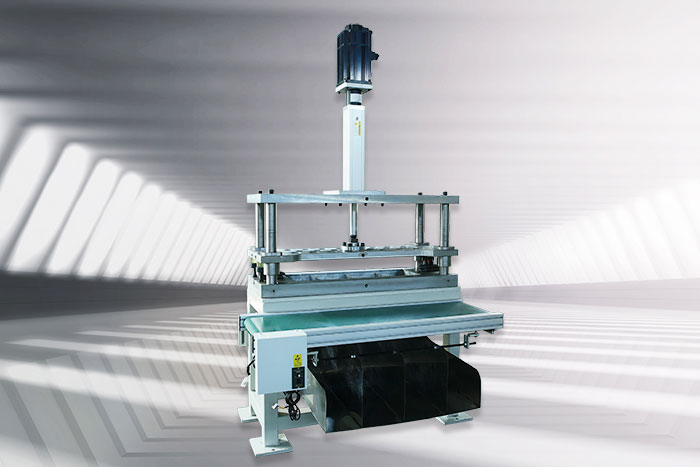

2. The unit with plastic extrusion machine and plastic molding machine, automatic feeding machine, punching and shearing unit together, synchronous work, to complete the required products.

3. The machine can be used for scrap material, waste and plastic particles mixed together to process and shape packaging products, PP, PE, HIPS and other plastic blister molding.

4. The machine can produce two or more layers, two color or more than two color products. Provide quality service for production.

5. The machine production speed is fast, the average area in 120mmX160mm calculation, each minute can produce 86 products, according to the thickness of the product requirements, can be adjusted at will to control the thickness of the product.

6. The machine reduces investment by about 20%, saves electricity by 35%, improves efficiency by 25%, reduces labor intensity and enhances economic benefits.

| Category/Model | φ65 screw | φ80 screw | φ90 screw |

| Motor power | 0.75KW | 0.75KW | 1.1KW |

| Operating speed | 25-32 S/min | 25-32 S/min | 25-32 S/min |

| Maximum forming area | 300x260mm² | 520x260mm² | 720x260mm² |

| Maximum forming depth | 60m | 60m | 70m |

| External dimension | 1900x650x1600mm | 1900x800x1600mm | 1900x900x1600mm |

| Weight | 600kg | 650kg | 740kg |

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our administration ideal for Fixed Competitive Price China Factory Supply New Design Single Nozzle Double Weighing Box Hollow Staple Fiber/Artificial Synthetic Down/Polyester Ball Fibre Stuffing Filling Machine, Our goal should be to create Win-win situation with our prospects. We imagine we will be your finest choice. “Reputation 1st, Customers Foremost. “Waiting for your inquiry.

Fixed Competitive Price China Filling Machine, Fully Automatic, We have more than 8 years of experience in this industry and have a good reputation in this field. Our solutions have won praise from customers worldwide. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.